A Look Back at the Inaugural gulfBID Expo

2006

For a number of years this was the official website for the Gulf ’s International Exhibition for Building & Interior Design (gulfBID) .

Content is from the site's 2006 archived pages.

Jumping ahead: the gulfBID Expo is now called the Gulf Construction Expo. It's current website can be found at: http://www.gulfconstructionexpo.com/

“GULFBID REINFORCES BAHRAIN’S STATURE - Bahrain is rapidly becoming one of the Middle East’s exhibition hubs and GULFBID, the building and interior design Expo, will further reinforce the kingdom as a destination of choice.”

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

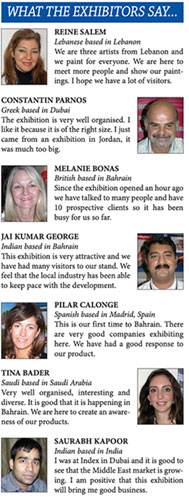

Welcome to gulfBID 2006

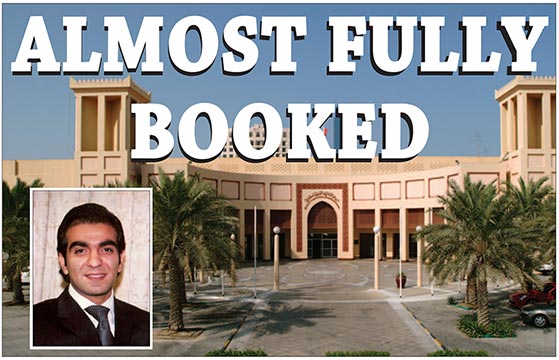

Almost Fully Booked

The BIEC ... state-of-the-art venue for the inaugural event; INSET: Shafeea

The first-ever Gulf ’s International Exhibition for Building & Interior Design (gulfBID 2006) is on course to be fully booked. Occupancy levels reached 90 per cent less than two months before the opening of the event, with more than 120 companies from all around the world enrolled.

That makes it the biggest event for building and interior design in the northern Gulf, and one of Bahrain’s milestone events.

gulfBID 2006 is being staged at the Bahrain International Exhibition Centre (BIEC) from May 16 to 18 and is attracting significant interest from regional and international exhibitors. The exhibition is being jointly organised by dmg world media and Hila

According to HCE general manager Abdulla Shafeea almost all spaces had been sold out, with extensive demand from all around the world. “We are introducing the region’s biggest construction and interior design for

“We are seeing a strategic shift in the exhibitions and convention sector into the northern Gulf underpinned by strong growth across the Middle East. Increasingly, Bahrain is re-emerging as a leading exhibition and conference hub for the region in parallel to Dubai. Importantly, with the heightened activity for building, construction and interior design taking place in Bahrain as well as Saudi Arabia’s Eastern Province, Kuwait and Qatar, gulfBID is well set to establish itself as the key exhibition platform for Bahrain, the Eastern Province and the northern Gulf,” says Shafeea.

DMG is the organiser of Big 5 and Index, the region’s largest construction and interior design exhibitions, being held in Dubai in November

dmg world media dubai managing director Bernard Walsh said that gulfBID would be based on those exhibitions and was eventually expected to become the third largest industry event in the region. “We are beginning by using only one hall, but we expect the exhibition

dmg is a wholly-owned subsidiary of Britain’s Daily Mail & General Trust. The gulfBID event will provide a platform for a wide range of products serving the construction sector, including building materials, heating and cooling technologies, water technologies and environment, flooring, cleaning and maintenance, glass and aluminium, roofing and cladding, real estate and architecture and engineering. It will also feature interior

It will also feature interior design products and services including furniture, fabrics, wall coverings, lighting, bathrooms and kitchens, artworks and accessories as well as marble and stonework. In addition to Gulf exhibitors, organisers have also received bookings from companies from the UK, Korea, Malaysia, China, Taiwan, Thailand,Germany, Spain and Italy.

gulfBID is targeting the northern Gulf building and interiors market and in addition to Bahrain, Saudi Arabia, Kuwait, and Qatar, the exhibition has a strong potential to service the Iraqi and Iranian markets

With high exhibitor interest seen in gulfBID, Shafeea is confident of strong visitor traffic backed by extensive media and marketing campaigns in Bahrain, Saudi Arabia, Kuwait and Qatar.

As the show is targeted at professionals, the business community and trade visitors, Shafeea is confident there will be strong visitor delegations from Saudi Arabia and the Gulf, reflecting the perceived strength of the event and its importance to the building and interiors sector at a time of intense construction activity, procurement and project development including Durrat Al Bahrain, Al Areen, Bahrain Bay and Bahrain Financial Harbour as well as projects across the region

~~~~~

A lot has transpired since the inaugural show. The last few years have been especially challenging with the world wide Covid pandemic affecting everything. The next Showcase for the Building and Construction Sector will be held at the Bahrain International Exhibition Center in March of 2022. The company my father works for has exhibited there every year. We no longer live in Bahrain, having moved to the US in 2015 when I was accepted at MIT as an undergraduate. Life is rather different now. The work I do as a web developer sometimes places me in conflict culturally with the way I was brought up. An example: For the most part, casinos, sports betting, and online gambling sites are illegal throughout the Middle East. Bahrain, as an Islamic country, has banned all forms of gambling. Although sports enthusiasts can freely enjoy a wide range of sports events in Bahrain, including Formula One racing (my favorite), no one is able to legally and freely bet real money on any of those sports events. Currently I am working on an affiliate online casino site, Online-Casino-Party.co where they promote real money slots. All of the featured online casinos are banned in the Middle East. My mother tsks and asked me if I have ever gambled online. I assure her I have not, but I admit I have tried several of the free versions of the casino games which are played with "free" money!

My father has announced that he will be attending the 2022 show in Bahrain. I think we will all be traveling with him. He will attend the show and then meet us later as we visit relatives. Hopefully the pandemic will be under better control by then so it will not disrupt our travel plans.

~~~~~

Inaugural show draws massive global interest

At the press conference are (from left) Index show manager Kim Willis, Mr Walsh, Mr Abdulrahman, Mr Middleton, and Mr Shafeea

More than 80 companies from around the world have so far signed up for the first Gulf International Building, Interior and Design Exhibition (gulfBID) – as the region’s booming construction and interior design industries fuel a massive interest in the new exhibition, set to open in Bahrain this May.

The exhibition – being held at the Bahrain International Exhibition Centre (BIEC) from May 16 to 18 – is being jointly organised by dmg world media and Hilal Conferences and Exhibitions (HCE). The event is targeting the Gulf ’s building and interiors market, including Bahrain, Saudi Arabia, Kuwait and Qatar, in addition to the Iraqi and Iranian markets. Speaking at a press conference held in Bahrain this month, HCE chairman Anwar Abdulrahman said that Bahrain’s geographic location as a neighbour to Saudi Arabia would benefit exhibitors greatly.

“Our proximity to an economy which is the industrial powerhouse in the region and which is home to over 27 million people, provides exhibitors with unmatched access to the region’s most important market, which is just 45 minutes away by road,” he said. “Within Bahrain itself, we are also witnessing massive growth and development, especially in the property and construction sectors. Never before has the kingdom witnessed so many multi-billion-dollar projects.”

HCE managing director Ronnie Middleton said the event was attracting exceptional interest. “The UK government has even agreed to financially support companies who want to take part in the exhibition,” he said.

DMG is the organiser of Big 5 and Index, the region’s llargest construction and interior design exhibitions, being held in Dubai in November. dmg world media dubai managing director Bernard Walsh said that gulfBID would be based on those exhibitions and was eventually expected to become the third largest industry event in the region. “We are beginning by using only one hall, but we expect the exhibition to grow rapidly every year,” he said. dmg is a wholly-owned subsidiary of Britain’s Daily Mail & General Trust.

The event will provide a platform for a wide range of products serving the construction sector, including building materials, heating and cooling technologies, water technologies and environment, flooring, cleaning and maintenance, glass and aluminium, roofing and cladding, real estate and architecture and engineering.

It will also feature interior design products and services including furniture, fabrics, wall coverings, lighting, bathrooms and kitchens, artworks and accessories as well as marble and stonework.

In addition to Gulf exhibitors, organisers have also received bookings from companies from the UK, Korea, Malaysia, China, Taiwan, Thailand, Germany, Spain and Italy. The Commerce and Industry Ministry’s efforts to market Bahrain abroad had encouraged Al Hilal Group to invest in Bahrain’s future as a regional exhibition hub, Mr Abdulrahman said. Industry and Commerce Ministry Assistant UnderSecretary for Foreign Trade Shaikh Daij bin Salman Al Khalifa said that Bahrain was pleased to have been selected as a venue for this event.

“It will bring the latest trends and developments in these vibrant and vital industries to trade professionals, construction companies and others concerned in Bahrain, Saudi Arabia and the rest of the GCC,” said Shaikh Daij. HCE general manager Abdulla Shafeea said that the exhibition was being held at a time of intense construction activity, procurement and project development, including Durrat Al Bahrain, Bahrain Financial Harbour and others.

“Already 70 per cent of the total space for gulfBID has been sold four months prior to the event,” he said. “This success demonstrates the strength of demand for building and interior products for what is set to become an annual exhibition.”

DEPUTY PRIME MINISTER OPENS GULFBID 2006

Inauguration ... Sheikh Ali cuts the ribbon, watched by Anwar Abdul Rahman (left), Bernard Walsh and Abdulla Shafeea (right)

TODAY’S SCHEDULE May 17, 2006 10.00 Exhibition opens 13.00

Gulf Construction magazine luncheon at Palm Hall, Bahrain International Exhibition Centre

19.00 Exhibition closes

FLYING START

The Gulf’s International Exhibition for Building & Interior Design (gulfBID 2006) got off to a flying start yesterday with Bahrain’s Deputy Prime Minister and Minister of Transportation Sheikh Ali bin Khalifa Al Khalifa opening the pioneering event at the Bahrain International Exhibition Centre (BIEC). Also on hand for the opening ceremony were other ministers, senior government officials, governors, MPs and ambassadors, underscoring the importance of the prestigious trade event for Bahrain

They included Works and Housing Minister Fahmi Al Jowder, Minister of Municipalities and Agriculture Ali Saleh Al Saleh, Minister of Water and Electricity Sheikh Abdullah bin Salman Al Khalifa, Minister of the Prime Minister’s Court Sheikh Khalid bin Abdullah Al Khalifa, President of the General Organisation for Youth and Sport Sheikh Fawaz bin Mohammed Al Khalifa, Manama Governor Sheikh Humood bin Abdullah Al Khalifa and Muharraq Governor Salman bin Hindi.

Jointly organised by Hilal Conferences and Exhibitions (HCE) and dmg world media Dubai, gulfBID enjoys the Royal patronage of Bahrain’s Prime Minister, Sheikh Khalifa bin Salman Al Khalifa.

Sheikh Ali toured the entire exhibition hall and talked to several of the international, regional and local exhibitors, keenly inspecting the range of products on display. “I am impressed by the number of companies taking part in the exhibition,’’ Sheikh Ali commented. ‘‘The Gulf offers a lot of opportunities and companies from all over the world are keen to take part in the region’s massive development.’’ Sheikh Ali also had words of praise for the event’s organisers, HCE and dmg world media Dubai

“I thank Al Hilal Group and its chairman Anwar Abdul Rahman for bringing such an important event to Bahrain,’’ he said. ‘‘Our government is firmly committed to supporting such initiatives which help enhance Bahrain’s standing. I wish the exhibition every success and I hope it grows bigger next year.’’

Meanwhile, Al Jowder said that the event could not have come at a better time for Bahrain. ‘‘We are witnessing a revolutionary period in the building materials industry and exhibitions such as this are ideal venues to launch new products,’’ he said. “Companies are spending a lot of money on research and development of new, economical and environmentally-friendly products. gulfBID will help these products to reach the end-user.’’

He said his ministry was keen to use the latest technology in housing and was studying the use of new materials in construction. Commenting on the first day of the show, HCE general manager Abdulla Shafeea said that the response had exceeded his expectations. ‘‘It has been excellent, and Bahrain’s government has extended us a solid show of support,’’ he said. ‘‘Even the visitor and exhibitor traffic turnout has exceeded our expectations.’’

dmg world media Dubai managing director Bernard Walsh said he was encouraged by the events of the first day. ‘‘I’ve talked to several of the exhibitors and most of them have informed me that the quality of the visitors has been extremely high,’’ he said. ‘‘And, I was also delighted to learn that some of them have already conducted serious deals.’’

As many as 110 exhibitors, from as afar as New Zealand, are participating at gulfBID, which is one of the largest construction and interior design events for the Northern Gulf. Positioned as a key exhibition platform for Bahrain, the Eastern Province of Saudi Arabia, and the markets of Qatar, Kuwait and even Iraq, gulfBID is expected to prove invaluable for exhibitors, whether for establishing firm contacts or winning lucrative business deals, while visitors have the opportunity to see, first hand, a diverse array of products and services, all under one roof. dmg is the organiser of Big 5 and Index, the region’s largest construction and interior design exhibitions, held in Dubai annually.

Experts say that the GCC is in the midst of a massive construction boom with nearly 2,000 projects under way, at a combined value of over $1 trillion and gulfBID 2006 is expected to prove a rewarding experience for exhibitors who are looking to boost their business in the Gulf’s construction hotspot, as well as to trade visitors who are seeking new contacts, products and services.

The inaugural three-day event runs until Thursday, May 18.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Key seminars kick off today

BUILDING and construction experts are set to take to the stage today with informative and educative seminars presentations at a two-day Industry Forum being held alongside gulfBID 2006. The forum is being held at Stand 1011 within the exhibition itself. Entrance is free to all exhibitors, trade visitors, delegates and members of the press

WEDNESDAY, MAY 17, 2006

11.00-11.20 am Insulating Concrete Forms (ICF), Mike Garret, CEO, BuildBlock MidEast. 11.25-11.45 am Increasing Speed AND Quality in Construction, Christian Jensen, Partner, Innovative Building Solutions, Eco Block.

11.50-12.10 pm Fresh Air, The Next Big Thing After Microwave, Hugh Sylvester, Eco Quest International.

12.15-12.35 pm Drainage/Removal At Source, Willie Clark, Tech Director, Aluline.

12.40-13.00 pm Aluminium Composite Panels, Uday Shetty, Marketing Director, Alukbond India. Break

15.00 -15.20 pm Role Of Processed Fly Ash (PFA) in Concrete, Anil Joshi, Marketing Manager, A R Al-Amin Industries.

15.25-15.45 pm Wood Coating, John Mendes, Sales and Development, Manager, Sadolin Paints.

15.50-16.10 pm Safety On Construction Sites, Alawi Shubber, Managing Director, Osho Centre. 16:15-16:35 pm The Magic Of Anti-Carbonation Coatings, Ranjan De, Technology Manager, Berger Paints.

16.40-17.00 pm New Innovations In Vibration Technology Coatings, Robert Smith, Product Manager, Makita Corporation (M H Al Mahroos).

THURSDAY, MAY 18, 2006

11.00-11.20 am Movie, Tamer Mahmoud, Import Department, Taki Factories.

11.25-11.45 am Jura Limestone and Solnhofen Limestone from Germany, Wolfram Glaudo, Architectural Engineer, Solnhofen Stone Group.

11.50-12.10 pm Architectural Visualisation And The Need For 3D Graphics, Tafseer Elahi, Marketing Manager, BlueBoxME.

12.15-12.35 pm Pipes & Fittings For Plumbing and Soundproof Drainage System, Osama Isa Al Thawadi, Managing Director, Arabian Gulf Associates.

12.40-13.00 pm Application Of Ceramic Tiles in Middle Eastern, Modern, and Traditional Architectural Decoration, Hesam Mousavizade, Paradise Palace Trading. Break

15.00-15.20 pm Less Cooling, More Daylight – A New German Technology, Dr Helmut Koester, Al Imtiaz.

~~~~~~~~~~~~~~~~~~~

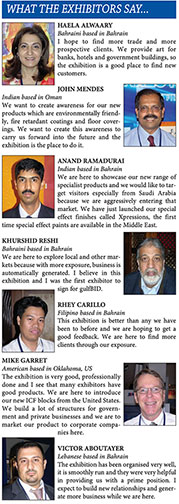

What The Exhibitors Said

“The construction market is buoyant and we are looking to establish a presence here. We are participating at gulfBID to support our local distributors in penetrating the market.” “Our goal is to enhance our sales volumes in the region and we anticipate that we will have a strong foothold in the local market within the next three to four years.” RAR (Lebanon)

“There are several new projects we are looking out for. Currently, the Bahraini market is allowing us the chance to grow and we expect the construction boom to continue for the next 10 years.” “We are happy with the response as there are quite a few visitors who have already been impressed by the range of our products.” ALASCO Group (Bahrain)

“This is the first time we are exhibiting in Bahrain, although we are regular participants at the Big 5 show in Dubai. Having achieved major success through the Big 5, we are now exhibiting at gulfBID with a view to tapping a different sector of the Gulf market.”

“Given its strategic location close to Saudi Arabia, Kuwait and other markets in the region, Bahrain offers a good potential to penetrate the market in the Northern Gulf. The Construction market in Bahrain is booming and we hope to clinch a number of deals here. Already, we have had considerable interest from sports companies.” Sport Mancha SL (Spain)

“This is the first time that we are participating at an exhibition in Bahrain and are planning to participate in other major shows during the year. We are looking at strengthening our sales network while introducing new products that cater to the demands of the market.” Saudi Industrial Paints Company (SIPCO) (Saudi Arabia)

“We are very pleased with the organisation of the Exhibition. It is quite excellent.” ECO Quest International (Bahrain)

“We have come to GULFBID to draw on the audience the exhibition attracts from Bahrain, Saudi Arabia and Qatar.” Carole Torbey / Magda Smadi (Lebanon)

“I believe in this exhibition and I was the first exhibitor to sign up for gulfBID.” Mubashir Hussain, Khazana (Bahrain)

“I have got some good and positive vibes from this exhibition. It is good to see the Saudis here as they are good customers.” Jane Dempster, Alpaca Products, (United Kingdom)

“We are at gulfBID to look at new opportunities. There is so much business coming from Saudi Arabia and Kuwait and many of our clients have an interest in Bahrain.” BlueboxME (Dubai, United Arab Emirates)

“The British Group has been impressed with the quality of visitors attending the show from both Bahrain and Saudi Arabia - professional architects, designers and owners with on-going projects. The organisers have managed the show most efficiently and we look forward to participating again in 2007.” Sue Graves, British Contract Furnishing Association (UK)

“This is my third time in the Middle East and I am pleased to say that the turnout is very good.” Laurie Hoskins, Gliderol Middle East, (United Kingdom)

“The exhibition is a good place to find new customers.” Heela Alwaary, Green Vision For Arts (Bahrain)

“I am very pleased with this exhibition. This is my first time in Bahrain and I would definitely come again.” Sidonie Stockinger, Muhldorfer GMBH & Co., KG (Germany)

EXHIBITORS

Launched in the region ... BuildBlock’s ICFs

ICF technology on show

BuildBlock Mideast, a subsidiary of Bahrain’s Hayat Group formed in collaboration with the US-based BuildBlock Building Systems, is promoting its range of insulating concrete forms (ICF) at the gulfBID 2006. According to the company, the products that are being introduced for the first time in the region have been well received by the various ministries, both in Bahrain and the UAE.

“There is much scope for the technology in the region as it offers enormous savings in terms of energy and construction costs,” says company chairman Hadi Al Alawi. “The concept has been well-received by the various ministries of Bahrain who have asked us to undertake a sample project that will allow us to explain the benefits of the system better.”

Buoyed by the response from the ministries, BuildBlock Mideast says that plans to set up a manufacturing facility in the kingdom are at an advanced stage and that the facility should be up and running in a couple of months from now. To be situated in the industrial are of Bahrain, the facility will include a 10,000 sq ft storage area and a 2,000 sq ft of area to house the presses. Initially, the facility will be equipped to manufacture 400,000 to 500,000 forms annually, but it could be scaled up to produce 8 to 10 million forms or more as and when the demand arises, says Mike Garrett, CEO and president of BuildBlock.

The company, which is at Stand 1E51, says that its ICF solutions can help save costs in terms of labour, energy savings and also time. The company’s ICF wall system comprises hollow foam blocks which are stacked into the shape of the exterior walls of a building, and is a combination of one of the finest insulating materials, expanded polystyrene (EPS), with one of the strongest structural building materials, steel reinforced concrete.

“The result is a protective wall of unmatched comfort, energy efficiency, strength, and noise reduction. Also, when combined with green building techniques, ICF walls contribute to LEED certification,” says Garrett. Elaborating further Garrett says: “The ICF walls offer energy efficiency of 60 to 70 per cent and has a R value of 35, which eliminates any drop in energy. Since they are easy to stack, the walls can be formed quite quickly with less labour. ICF also requires less shoring and bracing than conventional wall systems, which allows builders to cut the erection of walls by about 50 per cent.

“Being monolithic pours, and being devoid of cold joints, ICF walls are typically stronger. Concrete placed using the ICF system will normally achieve compressive strength that is 50 per cent greater than conventionally-placed concrete because of the temperature-controlled and moistureretaining environment of ICF systems.

“The forms also allow for both horizontal and vertical rebar reinforcement as the walls are stacked to form a grid, thereby strengthening the wall system further. “One of the outstanding features of a BuildBlock form is its completely symmetrical web design. This means two identical half-height forms are produced when the form is cut in half horizontally.

“This feature is particularly useful for step footings – an elevation change at the footing level. Step footings can be planned in increments of one block height (16 inches) or half-block height (8 inches). This will ensure an easy transition and that the forms will line up properly,” Garrett adds. In addition, owing to the thickness of the forms, much of the electrical and plumbing connections can also be wired into the walls using just a hot knife, he adds.

ICFs are ideal for all kinds of construction that include: homes, schools, healthcare facilities, municipal buildings and multifamily dwellings among other projects, he concludes

EXHIBITING

gulfBID is strategically located in Bahrain providing exhibitors with unique access not only to the rapidly growing building and interiors sectors within Bahrain but also to the Kuwait, Qatar and Saudi Arabian markets, all of which are easily accessible by road.

The Eastern Province of Saudi Arabia, home to the country’s massive oil wealth, is just an hour’s drive from Bahrain and gulfBID will prove a major attraction to anyone with a professional interest in these major industries.

The exhibition takes place at a time when the Gulf region is undergoing rapid and massive expansion. The price of oil coupled with the huge increase in liquidity in the market, as companies look for investment returns within the region, has fuelled a building and construction boom which is set to continue for years to come.

Visiting

If you are a specifier, buyer, importer, exporter, architect, engineer, contractor, interior designer, decorator, wholesaler, retailer, government or public sector official, gulfBID is for you.

The organisers have a proven track record for attracting thousands of manufacturers, suppliers and facilitators in every kind of construction and interiors discipline, from all over the region and the rest of the world – the sort of high quality exhibitors who will provide you with exactly the product or service you are looking for.

The breadth of scope of the manufacturers and suppliers exhibiting at gulfBID is massive. The key industries they will represent are as follows:

• Construction Materials

• Construction Systems & Technologies

• Construction Machinery

• Water Technology Materials & Systems

• Environmental Systems/Tools/Treatment

• Airconditioning & Insulation Materials

• Airconditioning Systems

• Refrigeration Systems & Machinery

• Cleaning & Maintenance Materials & Machinery

• Glass & Metal Systems & Tools

• Bathroom Products

• Bathroom Components

• Architecture & Consultancy

• Real Estate Development Projects

• Façades & Claddings

• Roof Materials & Systems

• Electrical & Plumbing Systems

• Office Furniture

• Hotel/Restaurant Furniture

• Leisure Furniture

• Residential Furniture

• Retail Furniture

• Interior Design

• Wall Coverings

• Flooring

• Fabrics & Upholstery

• Furniture & Upholstery

• Furniture Components

• Lighting

• Kitchens & Bathrooms

• Beds & Bedding

• Art & Accessories

• Signage & Display

• Marble, Granite & Ceramics

dmg world media Dubai Ltd are the organisers of the Big 5 Show and Index which are two of the largest trade exhibitions in the Middle East. dmg world media, a wholly-owned subsidiary of the Daily Mail & General Trust Plc, are one of the world’s leading trade shows organisers with over 400 events worldwide. dmg also publishes Gulf Interiors magazine, one of the region's leading journals for the sector.

All Hilal Group is one of the region's leading publishers and conference organisers. The company publishes leading trade journals for the Building & Construction, Industrial, Oil & Gas, Medical and Travel sectors. Gulf Construction magazine is the acknowledged leading publication for the region’s construction industry.

Al Hilal Group

PO Box 224

Manama,

Kingdom of Bahrain

Tel: +973 1729 3131

Fax: +973 1729 3400

gulfbid@tradearabia.net

dmg world media Dubai Ltd

Suite 203, Al Moosa Tower 2

PO Box 33817

Dubai, United Arab Emirates

Tel: +971 4 3319688

Fax: +971 4 3319480

dmgindia@emirates.net.ae

Summary of the Inaugural gulfBID Exhibition

The inaugural gulfBID Exhibition, which was held at the Bahrain International Exhibition Centre from the 16th to 18th of May, 2006, attracted 4,025 visitors.

The exhibition was officially opened by Sheikh Ali bin Khalifa Al Khalifa, the Deputy Prime Minister and Transportation Minister of the Kingdom of Bahrain. The gulfBID Exhibition attracted exhibitors from 17 countries representing 131 companies.

The show also featured national pavilions from the United Kingdom, Spain and Malaysia (please see section 3). The advertising campaign for gulfBID 2006 (204 advertisements placed) promoted the exhibition to a circulation in excess of 400,000 potential visitors across the Middle East.

The extensive PR campaign resulted in, to date, 38 articles, reaching a circulation in excess of 240,000 . The reaction of exhibitors to the gulfBID Exhibition was very favourable, with many comments referring to the high quality of visitors

The exhibitor survey conducted at the conclusion of the gulfBID exhibition indicated that 77.6% of exhibitors achieved the majority of their objectives. 54% of exhibitors rated the visitor quality as good or excellent with a further 40% rating it as fair. 82.4% rated the show organisation as good or excellent.

There was 95.9% satisfaction with the promotion of the show

Visitor Attendance Statistics

There were a total of 4,025 visitors. This included 3,825 trade visitors and an estimated 200 VIPs that came to the inauguration of gulfBID

Approximately 76% of registered visitors came from Bahrain, 19% from Saudi Arabia with a further 3% from other GCC countries. This demonstrates the effectiveness of the advertising and promotional campaign in not only drawing in the key visitors from Bahrain but also attracting a very important audience from the Eastern provinces of Saudi Arabia.

The visitor figures do not include approximately 300 individuals from the exhibiting companies, many of whom did significant business with each other at the show. The audience that came to the show was relevant to the exhibitors and of a high quality.

This can be seen in the comments made by the exhibitors (please see section 5) and in the results of the exhibitor questionnaires (please see section 8). The visitor registration process was monitored throughout the exhibition and the visitor cards and the data from the registration process have been retained for audit and inspection.

gulfBID 2007 - Next Year’s Exhibition

The gulfBID 2007 exhibition will take place at The Bahrain International Exhibition Centre from 15th - 17th May 2007.

The organisers have reserved two halls to accommodate the expected demand for space now that the exhibition has established itself as the premier event in the northern Gulf region for the construction and interiors sectors.

gulfBID 2007 - Next Year’s Exhibition

The gulfBID 2007 exhibition will take place at The Bahrain International Exhibition Centre from 15th - 17th May 2007.

The organisers have reserved two halls to accommodate the expected demand for space now that the exhibition has established itself as the premier event in the northern Gulf region for the construction and interiors sectors.